Servomex delivers the expert solution for methane measurements

Product Manager

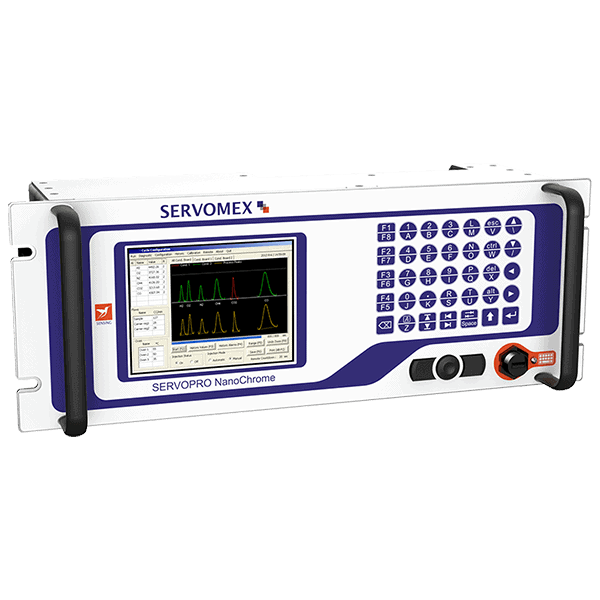

Our range of methane gas analyzers provides accurate monitoring of CH₄ in your process, using a variety of sensing technologies to deliver the best measurement results for each application. We offer the SERVOTOUGH SpectraExact 2500 and Laser 3 Plus Combustion as hazardous area methane testers, and a number of safe area SERVOPRO analyzers for industrial gas and purity applications. These include the MultiExact 4100, MultiExact 4200, HFID, Chroma, NanoChrome, and NanoChrome ULTRA gas analyzers. For CEMS applications, we have the 4900 Multigas, rounding off a comprehensive set of solutions for methane gas analysis.