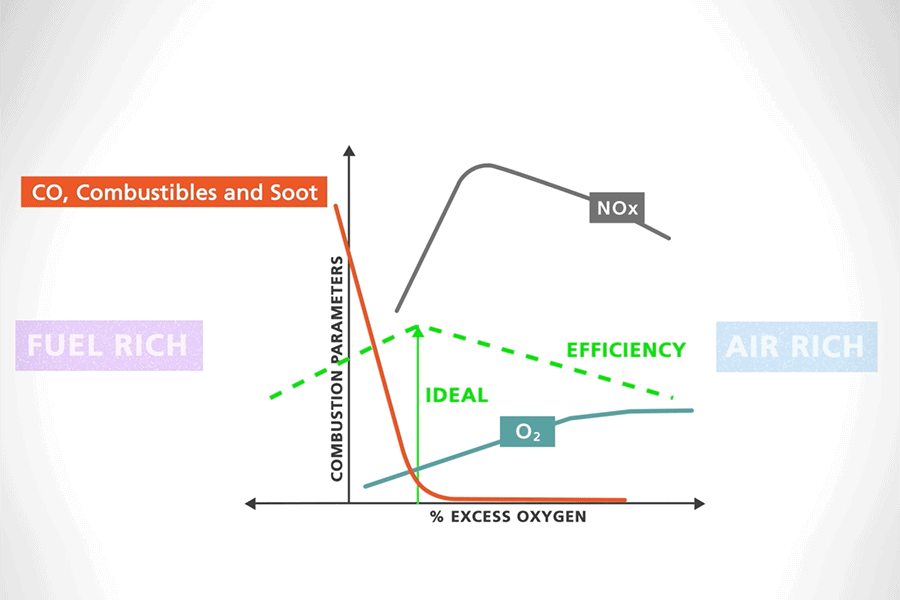

The combustibles measurement you need to control your combustion process

Process Oxygen, Zirconia & Oxygen Deficiency Product Manager

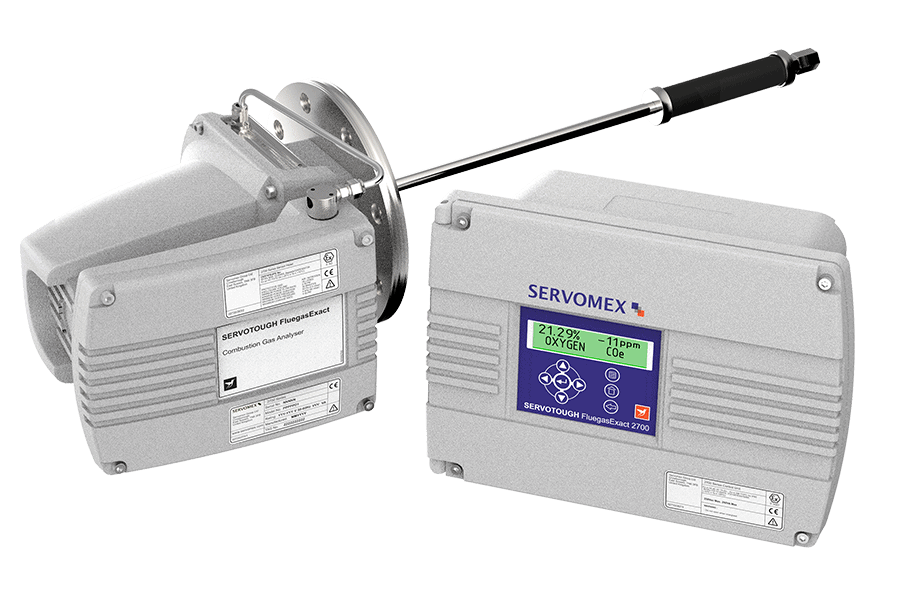

Servomex is the expert in combustibles gas analysis, with a trusted, reliable solution for combustion control measurements. Our SERVOTOUGH FluegasExact 2700 analyzer combines oxygen and combustibles measurements in a single device, helping to deliver effective combustion efficiency to the power generation and process industries.