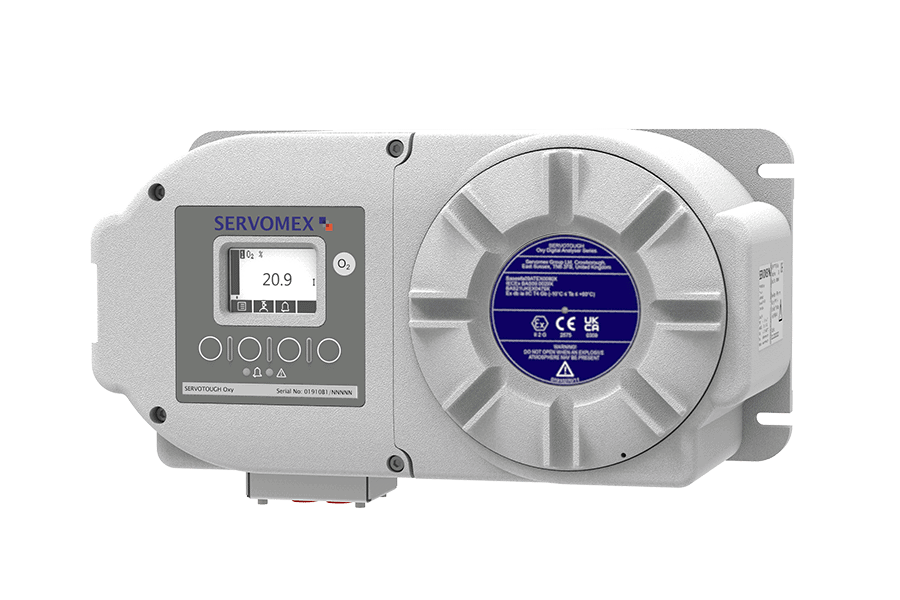

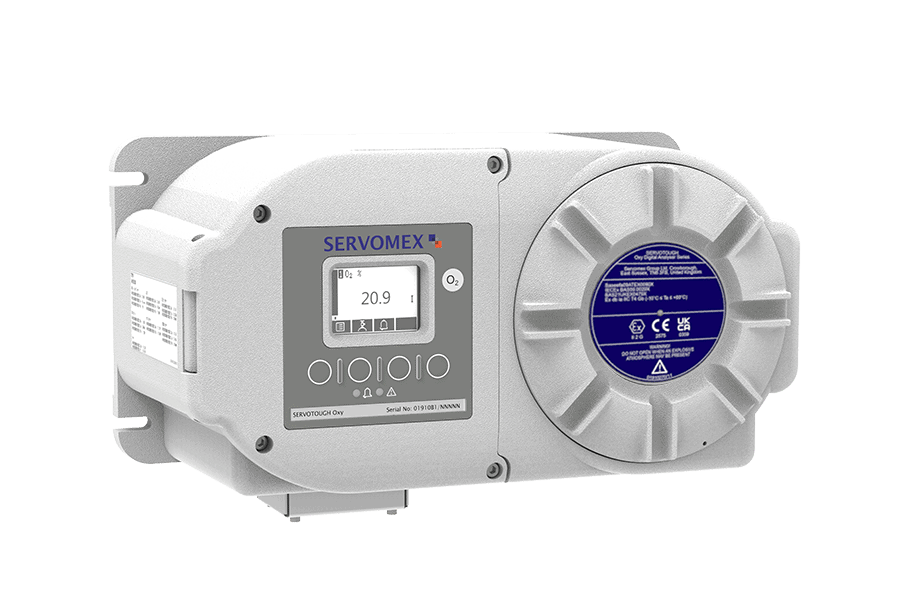

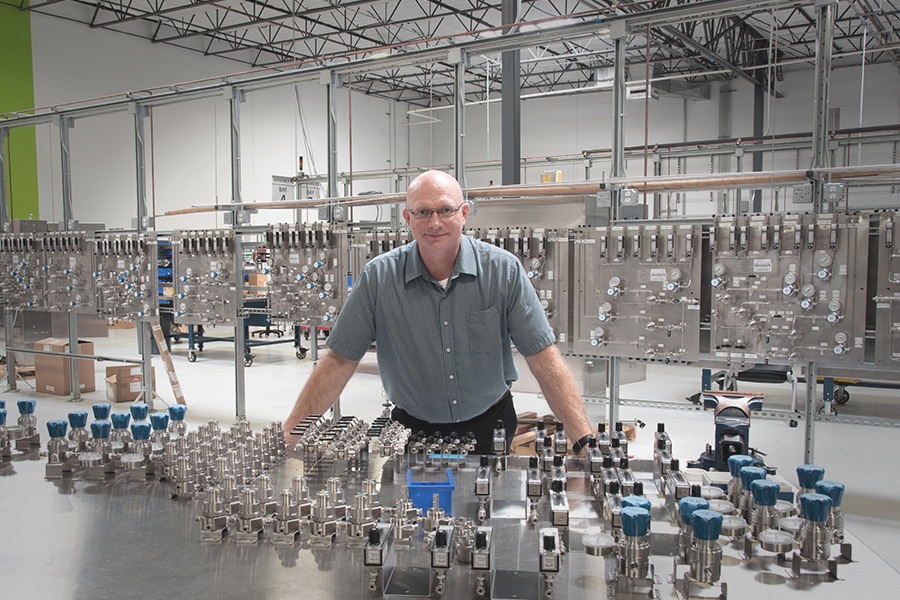

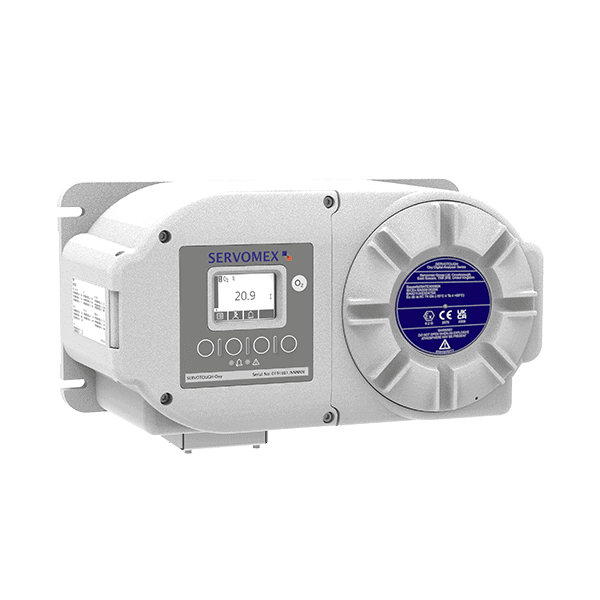

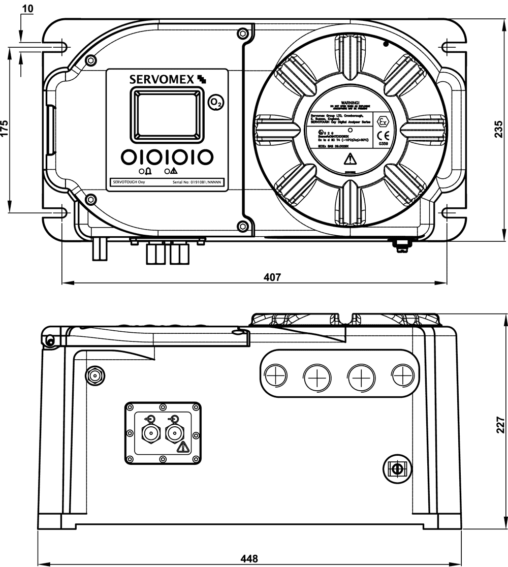

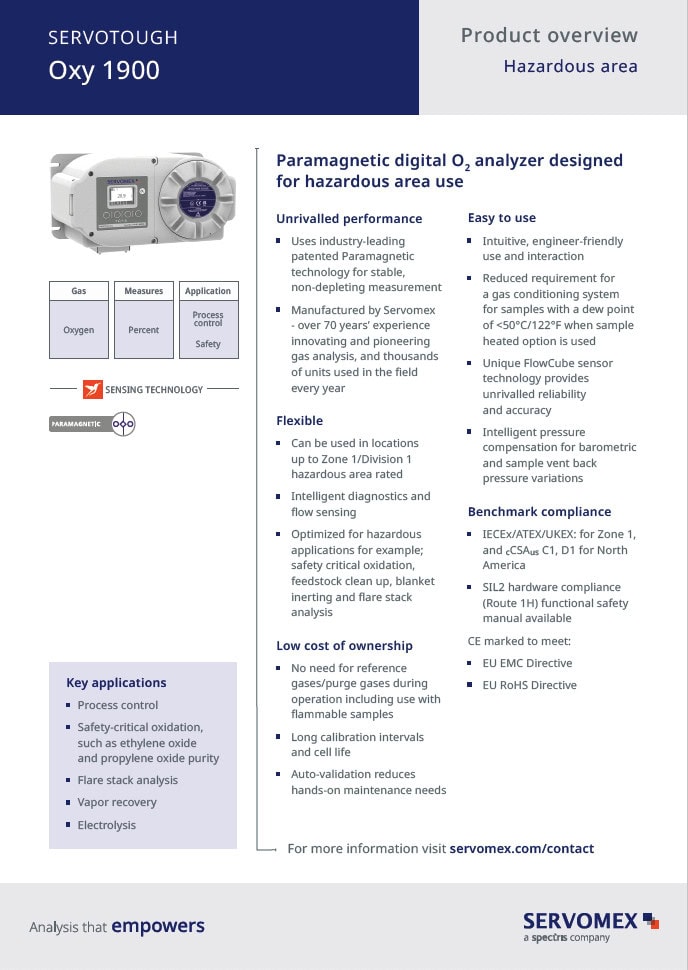

The SERVOTOUGH Oxy 1900 is a digital oxygen analyzer for hazardous area use.

Offering industry-standard features alongside revolutionary, value-added options, the Oxy 1900 oxygen (O₂) gas analyzer sets new standards of flexibility, stability and reliability from a single, cost-effective unit.

- Zone 1/Division 1 hazardous area rated

- Digital Paramagnetic O₂ measurements

- Heated sample gas compartment for stability

- Unique patented FlowCube flow sensor for enhanced safety

- Auto-validation / calibration option reduces hands-on maintenance

- Intelligent sample vent pressure compensation option

Setting new standards of flexibility, stability and reliability from a single, cost-effective unit, our base configuration model offers all the performance capabilities required for entry-level process oxygen measurements.

- Solvent-resistant Paramagnetic sensor

- 200ml/min sample inlet bulkhead option

- 0/4-20mA analogue output

- Six preconfigured signal interface relays

- Modbus RTU (RS485) communications

For users facing typical process control requirements, our mid-level configuration meets the challenges involved, delivering the same reliable oxygen measurements as the base model, supported by additional automated capabilities and value-added features.

- Has the same core options as Standard Variant 01

- Heated sample inlet/outlook bulkhead

- Auto-validation

- Autocalibration

For users who want to get the maximum from their analyser and be ready to meet every eventuality, we offer a full-configuration model for the most demanding process O₂ applications, with all available measurement options fitted.

- Has same core options as Standard Variant 02

- Internal sample pressure measurement

- Solid-state Flowcube flow sensing technology

Adding to our base level configuration build but with the new hydrogen resilient transducer option, this model offers all the performance capabilities required for entry-level process oxygen measurements with sample backgrounds containing hydrogen.

- Solvent-resistant, Hydrogen resilient, Paramagnetic sensor

- 200ml/min sample inlet bulkhead option

- 0/4-20mA analogue output

- Six preconfigured signal interface relays

- Modbus RTU (RS485) communications

Get a gas analyser ready to meet the specific needs of your unique applications with a user-configured option.

If one of our standard variants doesn’t match your requirements, we offer custom configurations to match your process precisely.

Get in touch with our experts and tell us what you need to overcome your process challenges. We’ll create, configure, and calibrate your gas analyser to ensure it performs exactly as you expect, delivering key benefits and premium performance.