Get trusted carbon monoxide measurements for your process

IP&E Spectroscopic Product Manager

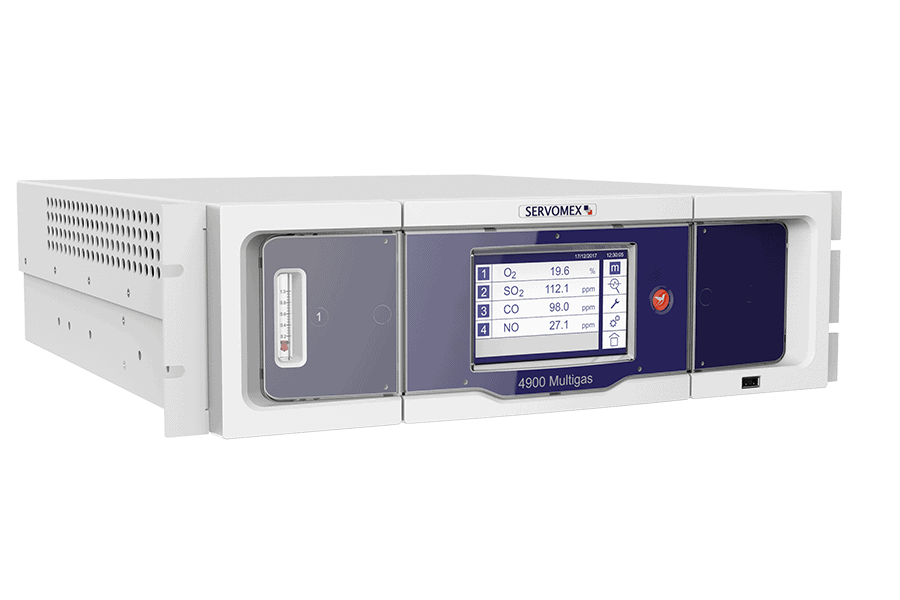

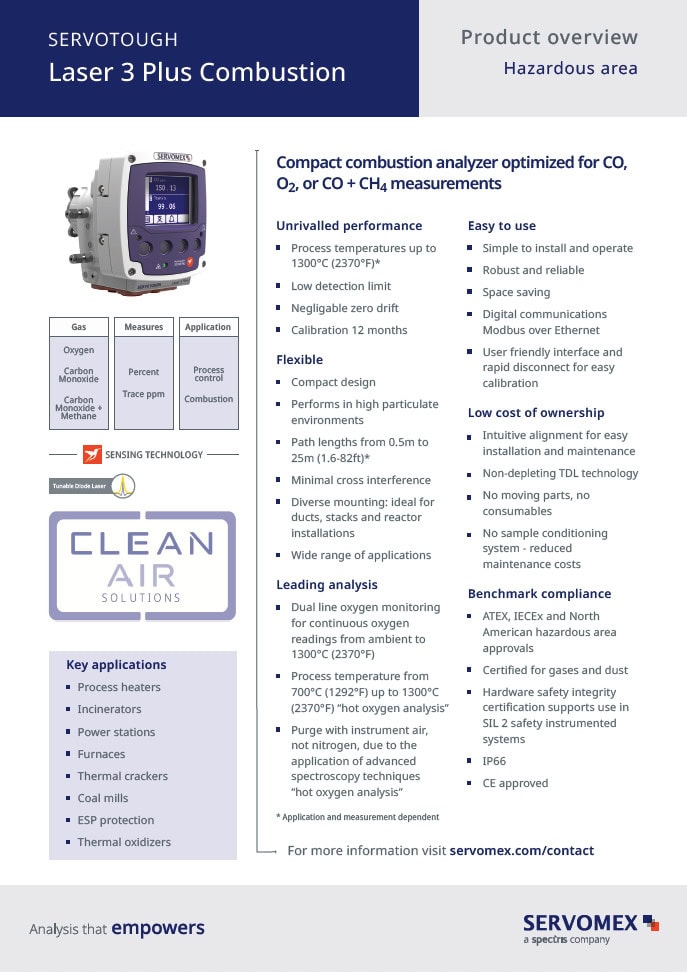

If you need to measure carbon monoxide (CO) for process control or safety applications, we have the gas analysis solutions required. Servomex delivers expert solutions for carbon monoxide measurements, using a range of sensing technologies for the best fit to your process. Our CO gas analyzer range utilizes technologies including Infrared, Plasma, and Gas Chromatography for low-level impurity detection, and Tunable Diode Laser or Spectroscopic sensing for combustion safety and process control. Servomex CO analyzers are available for both safe area and hazardous area operation.